The making of the silicon dial of the Ulysse Nardin Blast Free Wheel Marquetry watch

Last week, I was invited by Ulysse Nardin to attend the unveiling of the brand’s newest watch: a technical marvel that uses high-tech materials in a new way in the watch world. Of course, this brand is well known for thinking outside of the proverbial box – or in this instance, watch. This brand, after all, has brought us cutting-edge innovative timepieces like the crownless, hands-free Freak, and the Diver Net recycled materials watch, and more. Now, it deftly combines the art of watchmaking with high technology in the new Blast Free Wheel Marquetry watch with flying tourbillon escapement.

Ulysse Nardin Blast Free Wheel Marquetry watch retails for $137,200.

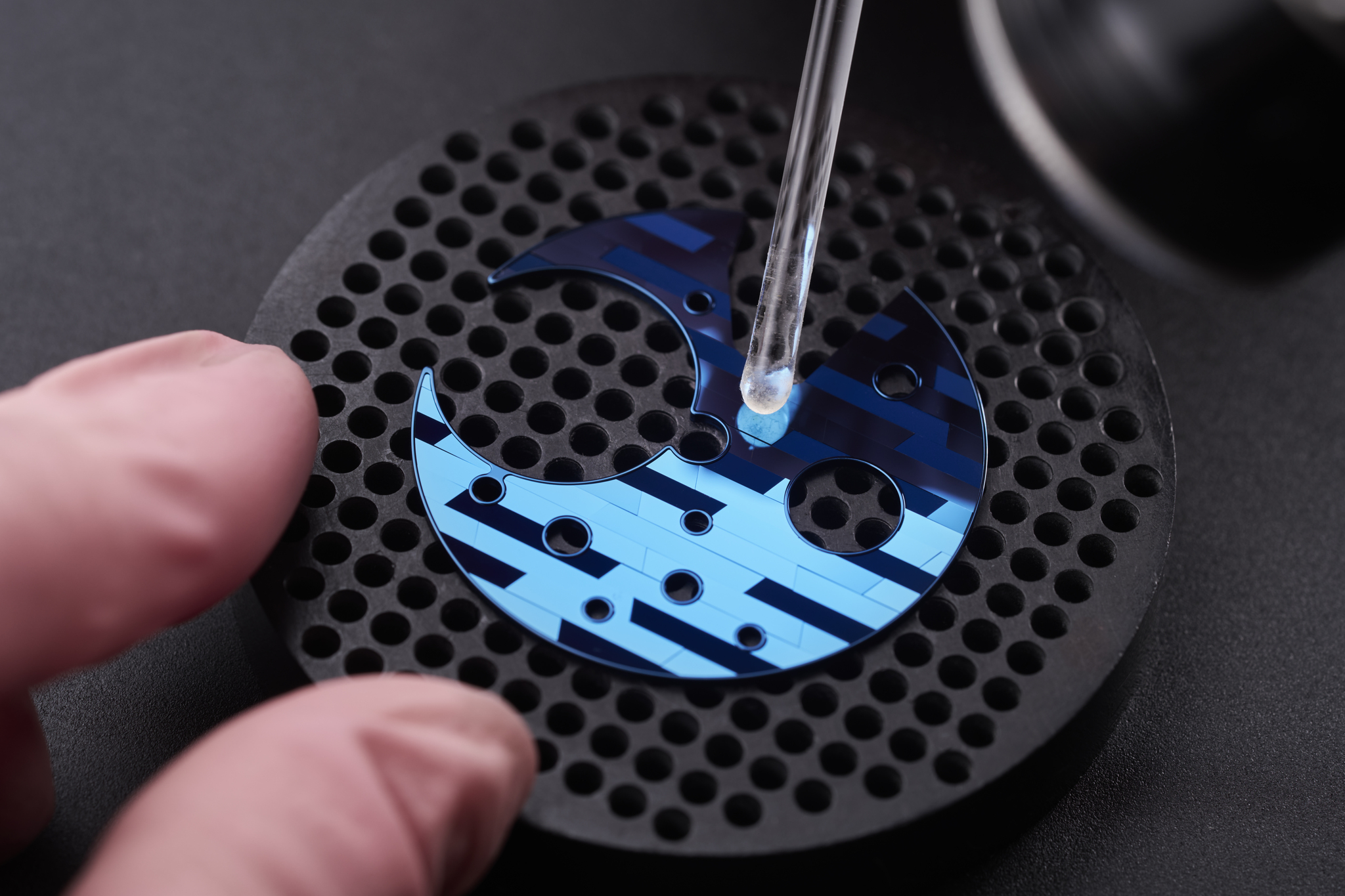

For the creation of this $137,200 watch, Ulysse Nardin turns to a material it has worked in for decades: Silicon. In fact, this brand pioneered in the use of silicon for movement parts, incorporating it into the iconic Freak watch in 2001. Now, though, it uses the light-weight silicon to create the blue marquetry artwork that serves as the backdrop for this watch.

The silicon marquetry dial consists of 103 bright blue marquetry pieces that vary in thickness and are finished in matte and mirror polish. The assembly of the tiny pieces of silicon takes days of tedious work, especially since the material is extremely fragile. Completing the ode to silicon, Ulysse Nardin for the first time embellishes the case back with a blue silicon plate surrounding transparent sapphire crystal cut outs for viewing more of the movement.

The crystal and case sides of the Ulysse Nardin Blast Free Wheel Marquetry watch allow for uninhibited views of the dial and movement parts.

Seemingly floating in air above the marquetry are parts of the UN-176 manufacture movement: the wheels, a flying barrel (with seven days of power reserve) at 12:00, and the tourbillon with Ulysse Nardin Anchor Constant Escapement consisting of 45 components alone and located at 6:00 on the watch.

The 45mm case is created in white gold with angled facets that were created via a complex laser process. The result is a geometric marvel that rivals the marquetry dial and, thanks to the brushed finish with some negative polished spaces, offers bold, contemporary appeal. The sapphire crystal is raised in box-like format to give a complete view of the movement and marquetry.

The making of this watch — from movement to dial — is no easy feat. Ulysse Nardin Blast Free Wheel Marquetry watch

The innovative 249-part UN-176 movement originally required two years of research and development to perfect and won the 2015 Grand Prix d’Horlogerie de Geneve Tourbillon prize. The brand’s proprietary Anchor Constant Escapement feature on the tourbillon features a circular frame with a pallet fork fixed in the center, supported in space on two blade springs less than a quarter of the thickness of a hair in diameter. The blade springs are constantly subjected to a bending force that maintains them and ensures an even force on the balance wheel for incredible precision throughout the watch’s entire power reserve.

Even the power reserve indicator (at 4:00) is unusual. It features three separate bands of metal, if three are present at the arrow, the watch is fully wound. When only one band is pointed to by the arrow, the watch is running out of reserve. The remaining components on the dial include a reduction gear, and winding mechanism. The watch is finished with a blue velvet-effect rubber strap and sold with a blue alligator leather strap, as well.

The case back of the Ulysse Nardin Blast Free Wheel Marquetry watch