At Donze Cadrans, jars upon jars of color for the enamel and lacquer occupy a wall.

Enamel dials have long been regarded as the pinnacle of luxury watchmaking, showcasing exquisite craftsmanship and timeless elegance. To truly appreciate the artistry and dedication behind these remarkable creations, I visited the renowned Donzé Cadrans factory, now owned by Ulysse Nardin, where the magic of enamel dials comes to life.

The colored powder is poured into a glass bowl where it is mixed with liquids and stirred to the right consistency.

Established in 1972 by master enamel maker Francis Donzé, Donzé Cadrans S.A. started as a niche company dedicated to the art of enamel dials. Little did Francis know that his specialized skills would one day garner worldwide recognition in the realm of Haute Horlogerie and ancestral watches.

Now owned by Ulysse Nardin, Donze Cadrans continues to also make dials for other watch brands.

With a deep-rooted commitment to preserving the art of enamel, Ulysse Nardin acquired Donzé Cadrans in 2011. This acquisition allowed the venerable enamel dial manufacturer to maintain its independence within the watchmaking industry while benefiting from Ulysse Nardin’s expertise and resources.

As I stepped into the Donzé Cadrans factory, I was greeted by a team of dedicated craftsmen who possess a rare combination of talent, passion, knowledge, and experience. These artisans are among the select few capable of mastering the intricacies of enameling. Donzé Cadrans has established itself as a leader in the field, supplying renowned watch brands, as well as Ulysse Nardin, with a wide range of dial techniques ranging from traditional opaque or translucent Grand Feu dials to the intricate Cloisonné and Champlevé. Every day, the craftsmen at Donzé Cadrans demonstrate their versatility and expertise in every piece they create.

Various stages of a white Ulysse Nardin enamel dial at Donze Cadrans.

As I ventured through the facilities at Donzé Cadrans, I had the opportunity to witness the various stages of dial production. It was fascinating to discover that some of the dials being created were destined for watches from other renowned brands—a testament to the trust and expertise that Donzé Cadrans has earned over the years.

Unlike certain styles of watch dials that can be largely produced by machines, enamel is a traditional art form that requires extensive human interaction. In fact, more than 90% of the enameling process at Donzé Cadrans is meticulously performed by hand, following a method that has remained unchanged since the 17th century. This level of craftsmanship and attention to detail sets Donzé Cadrans apart, as only a handful of brands possess the ability to create their own enamel dials.

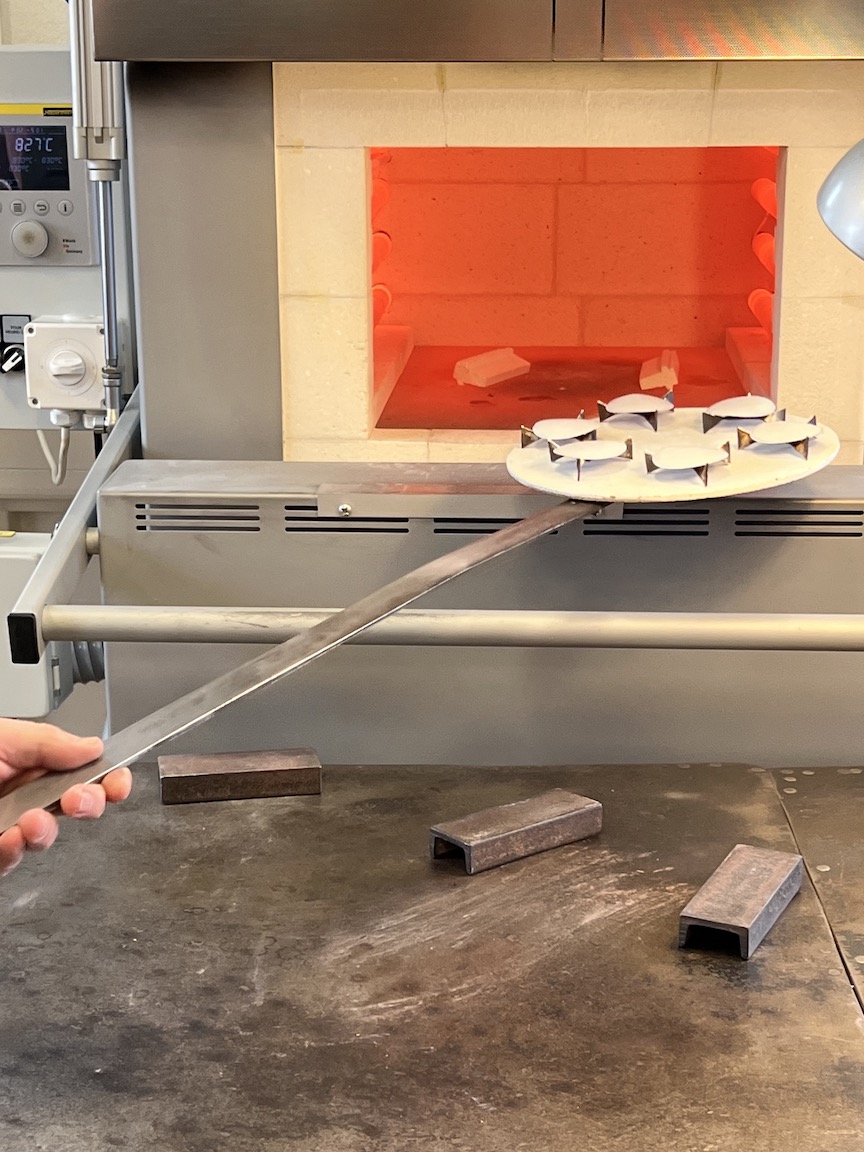

All enamel dials at Donze Cadrans are fired in a kiln like this one.

Visiting the Donzé Cadrans factory was an extraordinary experience that unveiled the remarkable craftsmanship and dedication involved in creating enamel dials. Witnessing the delicate process firsthand and appreciating the artistry behind these exquisite creations is a must-do for luxury watch lovers. It opens eyes into an entirely different realm of watchmaking and art and the visitor understands that each dial is a labor of love, with the craftsmen pouring their knowledge and expertise into every intricate detail.

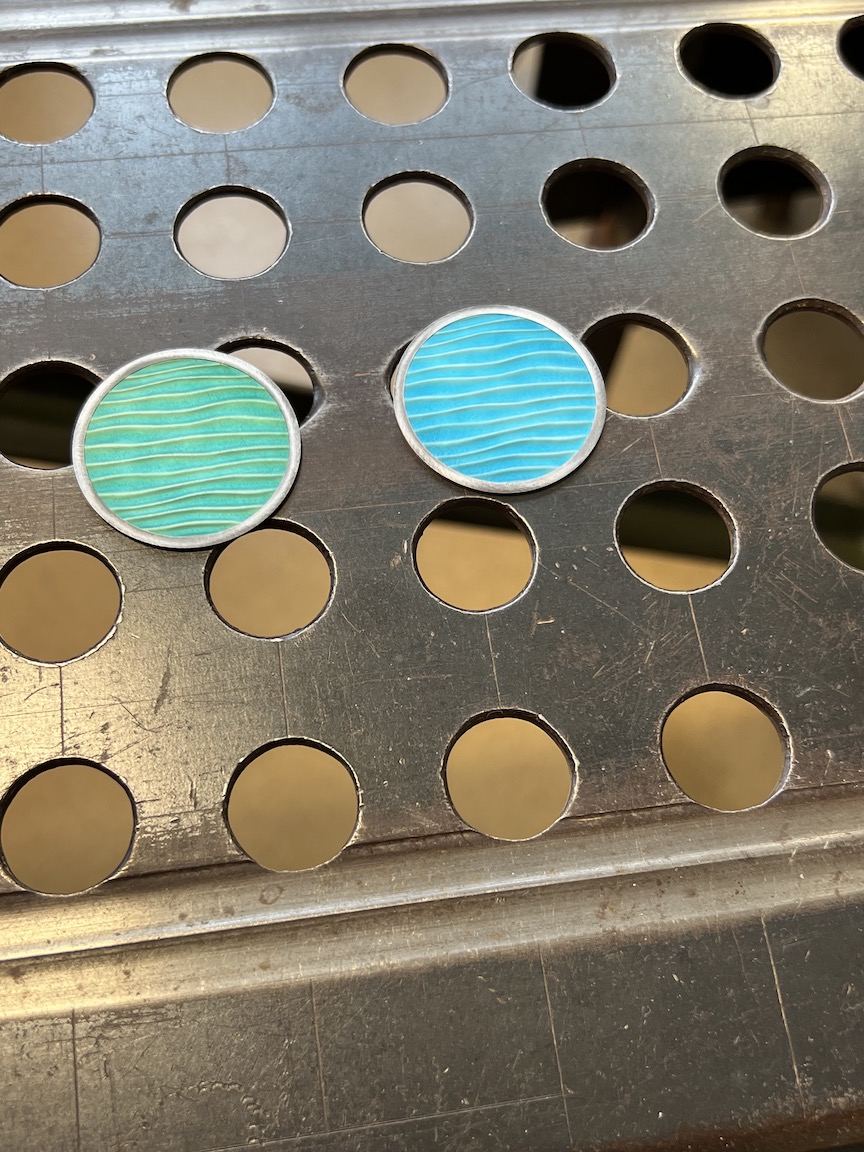

Once painted and heated, the enamel dial takes on a different color as it cools. The one on the right is hot and the one on the left is not.

Unlike with other portions of watchmaking, where you wander through sterile rooms with big equipment and CNC machines and bench after bench of watchmakers, Donze Cadrans is small and feels more like you are walking into an artist’s studio than a watch brand facility. It is as though you are visiting a house with many rooms and very friendly artisans.

The Realm of Enamel Work At Donze Cadrans

While the enamel processes themselves may share similarities, each technique requires exceptional precision and skill. Enamel dial making is a true art. It requires patience, dexterity and hand craftsmanship at every stage of the game. Each type of enamel work has its own intricacies, and Ulysse Nardin’s Donze Cadrans has them all mastered.

Dial making is a time consuming and meticulous process.

In fact, the brand is highly adept at the creation of its “Grand Feu” enamel dial, which typically is created in either a white, beige, or opaque color. The white is the most difficult to achieve and it’s one of the most highly sought after. Ulysse Nardin delivers.

The art of enamel specifically refers to vitrifiable products that result from the fusion, vitrification, or sintering of mineral materials melted at temperatures exceeding 500°C. Most dials go through multiple heating and painting processes — leaving them vulnerable to bubbles or cracks at every stage. In the brand’s presentation room, there is small jar with “reject” dials in it — the fact that those dials could fit in two hands cupped together is a testament to the precision work of the artisans.

Hand painting a Ulysse Nardin Manera dial at Donze Cadrans.

Another specialty of the brand’s is the combination art of guilloche and enamel. The art of Guilloché enamel dial production requires a masterful combination of technical skill, patience, and artistic vision. First, the craftsman (or woman) delicately carves precise patterns onto the dial, resulting in mesmerizing textures that capture the light and create a visual depth that is truly captivating. The meticulous attention to detail and the incorporation of precious metals elevate these dials to the realm of extraordinary horological artistry. Then hand enamel is added to the meticulous engraving for incredible allure.

Ulysse Nardin Freak Marquetry watch

As I observed the artisans meticulously working on these remarkable enamel dials at the Donzé Cadrans factory, it became clear that their dedication and mastery were essential in producing timepieces of unparalleled beauty and sophistication. By offering a variety of enamel dial types, including the prized Grand Feu and Guilloché enamel, Donzé Cadrans continues to showcase its commitment to preserving the traditions of this timeless craft. With their expertise and passion, the artisans at Donzé Cadrans breathe life into each dial, creating a masterpiece that seamlessly combines heritage, artistry, and innovation.

I would have also been able to report on the Ulysse Nardin watchmaking factory, but due to flight delays, I unfortunately missed that portion of the tour. However, that’s not necessarily bad. The hope is I get to go again to visit Ulysse Nardin and witness the brand’s watchmaking skills firsthand and maybe also get to see some of the top secret silicium and DiamondSil making – but that is another story.

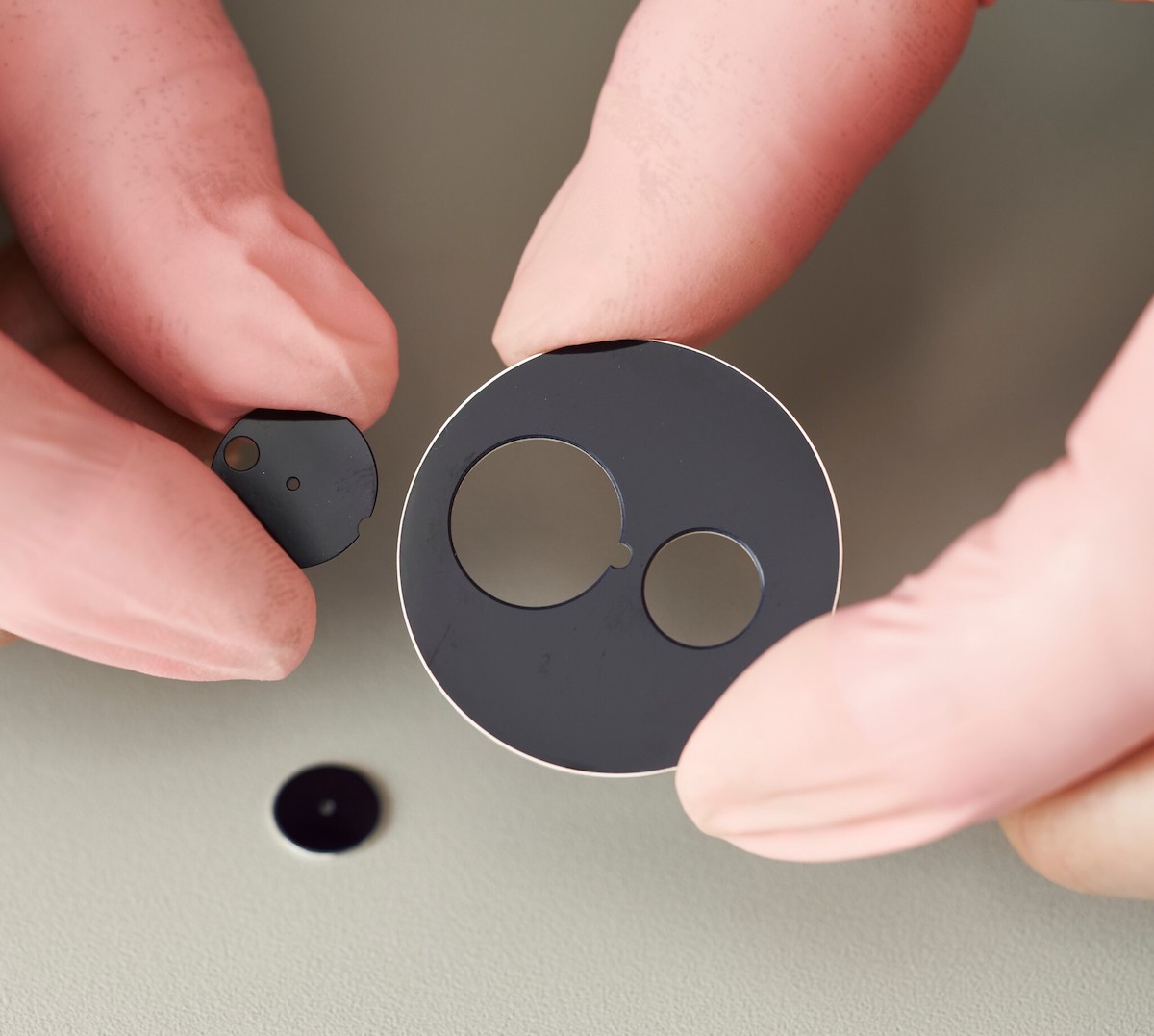

Cutting sundials after the dial has been enameled.